Understanding Electromagnetic Shielding

What is Electromagnetic Shielding?

Electromagnetic shielding is a technique used to block or reduce electromagnetic fields (EMFs) by using barriers made from conductive or magnetic materials. By creating a shielded environment, it becomes possible to mitigate the effects of electromagnetic interference (EMI) and radio-frequency interference (RFI). This interference may disrupt the normal functioning of electronic devices, leading to reduced performance and reliability. Understanding the principles behind electromagnetic shielding is crucial for industries where electronic integrity is vital, such as telecommunications, medical device manufacturing, and aerospace engineering.

Importance of Shielding in Today’s Technology

In our rapidly advancing technological landscape, the need for effective electromagnetic shielding is more pertinent than ever. Modern electronic devices operate at high frequencies and are often densely packed, which increases the likelihood of interference. EMI can lead to signal degradation, data loss, and even device failure. For example, in medical settings, insufficient electromagnetic shielding can compromise the performance of essential equipment such as MRI machines. Consequently, industries prioritize the implementation of reliable shielding solutions to protect sensitive electronics from external noise and to ensure compliance with safety regulations.

The increasing prevalence of wireless devices, Wi-Fi networks, and other forms of communication also skews the electromagnetic spectrum, reinforcing the need for effective electromagnetic shielding materials. To learn more about various electromagnetic shielding materials, industry professionals can explore diverse options that adapt to specific shielding requirements or operational environments.

Electromagnetic Shielding Materials Overview

Electromagnetic shielding materials can be classified based on their structure, electrical conductivity, and effectiveness against different types of electromagnetic radiation, whether it be radiated or conducted. Common materials used for shielding include metals, conducting polymers, ceramics, and composites. The selection of a shielding material depends on various factors such as frequency range, shielding effectiveness against specific wavelengths, physical properties, and cost considerations. Understanding these differences is crucial for selecting appropriate materials for electromagnetic shielding applications.

Types of Electromagnetic Shielding Materials

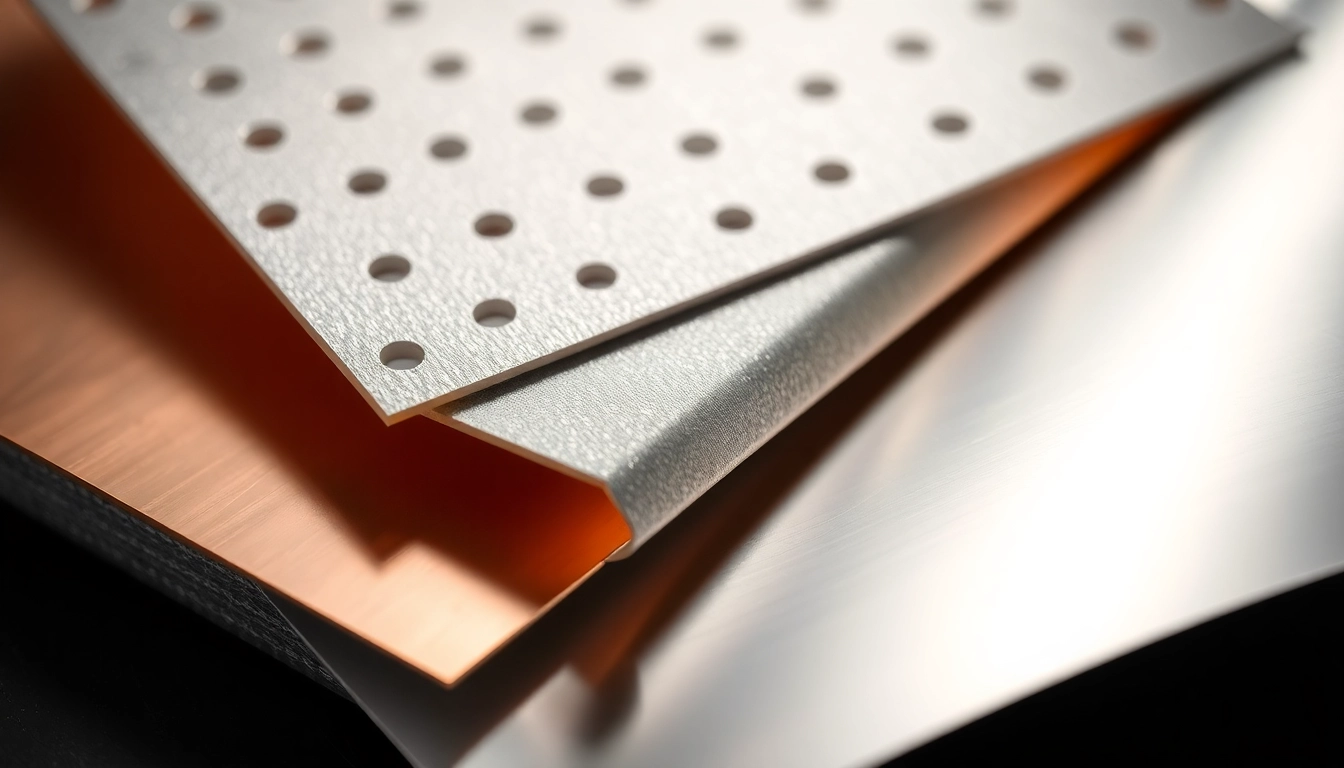

Common Metals Used for Shielding

Metals are among the most widely utilized materials for EMI shielding due to their high electrical conductivity and ability to reflect and absorb electromagnetic waves. Here are some of the most commonly used metals in electromagnetic shielding:

- Copper: Known for its exceptional conductivity, copper is considered the gold standard for EMI shielding. Its effectiveness stems from its ability to attenuate both electric and magnetic fields, making it a preferred choice for a variety of applications.

- Aluminum: Lightweight and cost-effective, aluminum offers good shielding properties, especially at low frequencies. Its resistance to corrosion further enhances its usability in various environmental conditions.

- Steel: Often used for structural shielding, steel provides robust protection and is particularly effective in high-frequency applications. Pre-tin plated steel enhances corrosion resistance while ensuring adequate shielding.

- Nickel: Nickel-coated materials are known for their durability and resistance to oxidation, making them suitable for long-term shielding applications.

- Brass: Not commonly used on its own, brass is often an alloy in applications requiring moderate shielding effectiveness combined with strength.

Effectiveness of Conductive Polymers

Conductive polymers represent a significant advancement in electromagnetic shielding technology. These materials combine the lightweight, flexible nature of plastics with the electrical properties of metals. Commonly used conductive polymers include polyaniline and polyethylene, which can be blended with carbon nanotubes or metallic powders to enhance their shielding performance.

Conductive polymers offer several advantages, including ease of processing and application, making them attractive for a range of products, from flexible circuit boards to architectural coatings. While they may not provide the same level of shielding as metals in all frequencies, their versatility in applications and manufacturing processes has led to their growing popularity in industries seeking lightweight solutions without a significant compromise on performance.

Emerging Materials in EMI Shielding

Recent advancements in material science have led to the development of novel materials that provide enhanced shielding properties. Some of these emerging materials include:

- Graphene: Known for its exceptional electrical conductivity and strength, graphene has shown promising results in electromagnetic shielding applications. Its role as a composite filler offers significant potential in enhancing the performance of traditional materials.

- Metal Nanocomposites: By combining metals with nanoparticles (such as silver or gold), researchers have developed composite materials that exhibit high shielding effectiveness at reduced thicknesses.

- Carbon Nanotubes: Due to their unique electrical and thermal properties, carbon nanotubes can be utilized as effective EMI shielding components when integrated into polymer matrices.

- Hybrid Materials: Combining multiple types of materials, such as polymers, metals, and ceramics, can yield improved shielding properties across different frequencies, addressing specific needs in diverse applications.

Applications of EMI Shielding

Shielding in Electronic Devices

Electromagnetic shielding plays a critical role in the design and operation of electronic devices. From smartphones to computers and home appliances, effective shielding minimizes interference from external sources, ensuring optimal performance. Shielding techniques may involve the implementation of conductive enclosures, filters, and grounding techniques, tailored to the unique requirements of each device.

Usage in Industrial Environments

In industrial settings, EMI shielding is essential in protecting sensitive equipment from the effects of nearby machinery and electronic systems. Shielding enclosures and barriers are often employed to contain the electromagnetic emissions from industrial processes, safeguarding other electronic devices. Industries such as manufacturing and aerospace benefit substantially from implementing robust shielding techniques.

Protecting Sensitive Equipment

Some medical devices, laboratory equipment, and telecommunication systems require additional protection against electromagnetic interference due to the critical nature of their functions. For instance, MRI machines must be shielded from external electromagnetic waves to maintain image quality and diagnostic accuracy. Various shielding techniques, including RF enclosures and conductive coatings, are deployed to mitigate interference risks, ensuring equipment reliability and safety.

Choosing the Right Shielding Material

Factors to Consider When Selecting Materials

When selecting electromagnetic shielding materials, it is essential to consider several key factors that influence the effectiveness and applicability of the materials, including:

- Frequency Range: The intended frequency range of the electromagnetic radiation must be considered to ensure that the selected material effectively attenuates those frequencies.

- Shielding Effectiveness: Each material has unique performance metrics; understanding the shielding effectiveness (SE) is vital in determining the best material for a specific application.

- Environmental Conditions: The operating environment can significantly impact material performance. Considerations such as temperature, humidity, and exposure to chemicals all influence material selection.

- Weight and Flexibility: In applications where weight is a concern (such as mobile devices or aerospace), lightweight materials can offer shielding without adding significant bulk.

- Cost: The cost of the materials should be assessed against their performance to ensure that the chosen option is within budget while delivering adequate protection.

Comparing Cost vs. Performance

When evaluating electromagnetic shielding materials, a comprehensive cost-benefit analysis is crucial. Costly materials may offer high shielding effectiveness but might not be feasible for large-scale applications. Conversely, less expensive materials could provide adequate shielding for specific situations but may require thicknesses or configurations that limit usability.

It is common for engineers to prototype multiple materials and configurations to identify the most suitable balance between cost and performance. Practical testing, along with modeling and simulation processes, can guide informed decisions in material selection.

Best Practices for Implementation

Successful implementation of electromagnetic shielding materials hinges on several best practices, including:

- Conducting a Comprehensive Assessment: Before selecting materials, perform a thorough evaluation of the operational environment and the specific electromagnetic interference threats present.

- Identifying Application Requirements: Understand the unique shielding needs of the devices or spaces involved, whether it demands flexible shielding for portable electronics or more robust shielding in fixed installations.

- Ensuring Proper Installation: Flaws in the installation process can severely compromise shielding effectiveness. Utilize skilled professionals who understand the nuances of EMI shielding to guarantee successful implementation.

- Testing and Validation: Following the installation, rigorous testing must be conducted to assess shielding effectiveness and ensure that the material is performing as expected.

Future Trends in Electromagnetic Shielding

Innovations in Shielding Technology

The field of electromagnetic shielding is continually evolving, driven by technological advances and the increasing demand for higher performance. Key innovations include:

- Smart Materials: Incorporating sensors and electronics within shielding materials can create ‘smart’ solutions that adjust in real time to varying electromagnetic environments.

- Nanotechnology: Advances in nanotech promise to enhance the shielding effectiveness of materials significantly while reducing thickness, thus preserving flexibility and reducing weight.

- 3D Printing: The growing capabilities of 3D printing open pathways for the creation of custom-designed shielding solutions, facilitating rapid prototyping and more efficient use of materials.

Sustainability in Shielding Materials

As industries increasingly prioritize sustainability, there is a growing interest in utilizing eco-friendly materials for electromagnetic shielding. Innovations may arise from recycled materials or biodegradable polymers, offering effective shielding with a reduced environmental footprint. The industry is expected to see further developments in sustainability-focused materials that align with stringent environmental policies while maintaining effective performance standards.

Predictions for the Industry

The electromagnetic shielding industry will likely evolve towards integrated solutions that combine different materials tailored to specific applications. The push for miniaturization in electronics will necessitate continued research into lightweight yet effective shielding options. Furthermore, as wireless technology continues to proliferate, demand for innovative shielding solutions is expected to grow, fostering further advancements in material design and manufacturing processes.