Understanding Industrial Heat Lamps

What Are Industrial Heat Lamps?

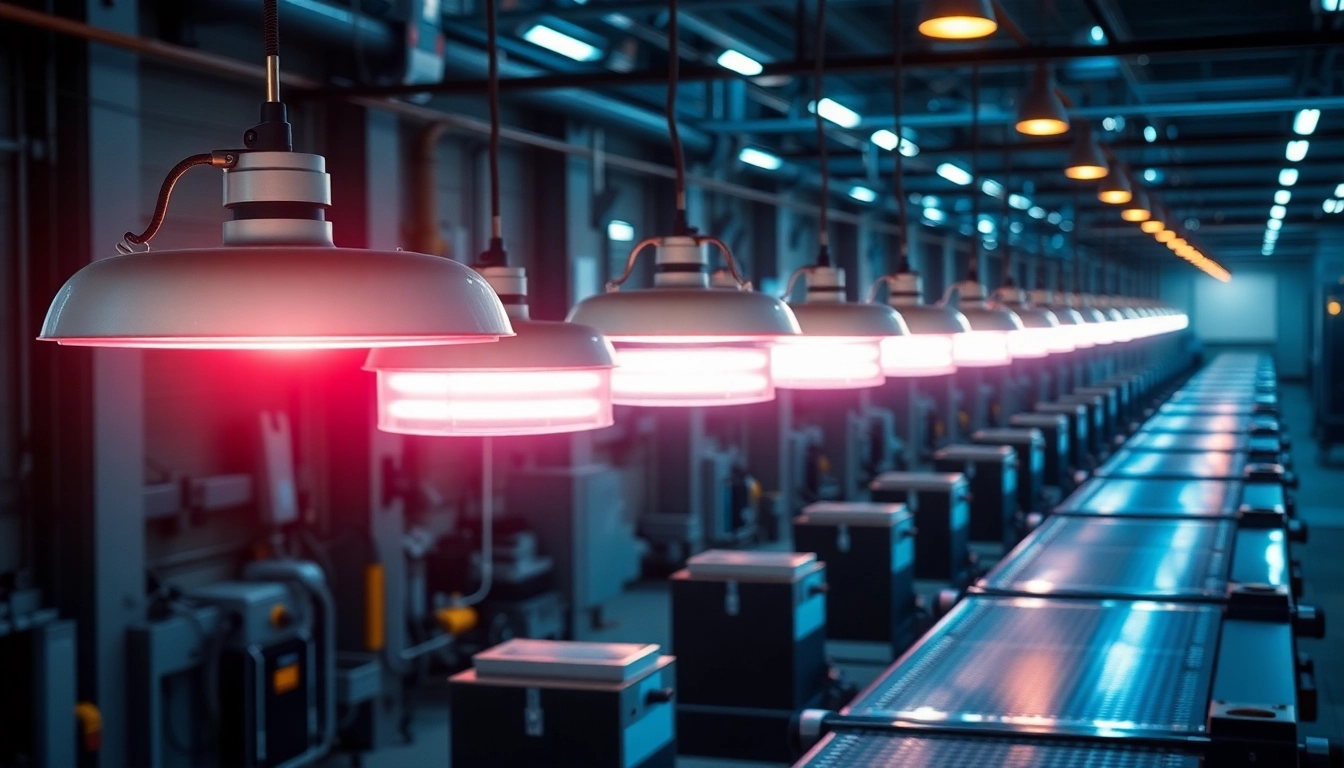

Industrial heat lamps are specialized heating devices designed to emit infrared radiation for various applications. These lamps utilize infra-red technology to deliver heat directly to objects without needing to heat the air in between, making them highly efficient. Different types of industrial heat lamps, including short wave, medium wave, and long wave emitters, have been developed to suit specific use cases across various industries.

Manufacturers like Huai’an Infrared Heating Technology provide a comprehensive range of industrial heat lamps that adapt to specific industrial needs, optimizing heating processes in areas such as automotive, food services, and printing industries.

Benefits of Using Industrial Heat Lamps

Adopting industrial heat lamps comes with multiple advantages: efficiency, versatility, and cost-effectiveness. They are designed to reduce energy costs considerably while providing targeted heating solutions, which is pivotal in modern industrial operations. By utilizing radiant energy, these lamps minimize heating times and maximize production throughput.

Furthermore, their adaptability allows them to be used in various applications, from drying surfaces quickly in manufacturing to providing warmth in outdoor dining establishments. Overall, they enhance operational productivity while contributing to sustainability efforts through improved energy efficiency.

Applications Across Industries

Industrial heat lamps cater to a broad spectrum of industries. For instance:

- Automotive Industry: Used for drying paint and curing adhesives swiftly, thus accelerating production timelines.

- Food Services: Ideal for keeping food warm without further cooking, thereby preserving texture and flavor.

- Printing Industries: Essential for drying inks quickly, which improves turnaround times and enhances the quality of printed materials.

- Manufacturing Facilities: Provide consistent heating for processes such as pre-heating metal components or drying coatings.

The versatility of industrial heat lamps confirms their essential role in increasing the efficiency of processes across varied sectors.

Types of Industrial Heat Lamps

Short Wave vs. Medium Wave Industrial Heat Lamps

The classification of industrial heat lamps into short wave and medium wave categories is based on the wavelength of the emitted infrared radiation. Short wave industrial heat lamps produce infrared rays of around 1,000 to 1,500 nanometers and are known for their rapid heating capabilities. These lamps are highly effective in applications requiring quick heat penetration such as automobile drying processes.

Conversely, medium wave industrial heat lamps, with wavelengths ranging from 1,500 to 3,000 nanometers, deliver a more moderate heating intensity, making them suitable for processes that require a gradual heating approach. Industries often leverage both types of lamps depending on specific requirements, combining strengths for increased efficiency.

Long Wave Industrial Heat Lamps Explained

Long wave industrial heat lamps operate within the spectrum of 3,000 nanometers and above. These lamps emit infrared radiation that heat surfaces more gently and are known for their uniform heating properties. Long wave lamps are often used to cure coatings or varnishes that require a sustained heating environment without overheating the substrates.

They are particularly favored in applications where heat sensitivity is a concern, preventing damage to delicate materials while still achieving efficient heating and drying.

Specialty Industrial Heat Lamps for Specific Uses

Beyond standard offerings, various specialty industrial heat lamps are engineered for very specific applications. For example, infrared curing lamps designed with specialized coatings can reduce glare while maximizing output. Lamps integrated with advanced features such as built-in timers or remote controls allow for added convenience and precision in managing heating tasks efficiently.

Each specialty lamp showcases advanced manufacturing techniques and insights into industry-specific demands, setting them apart as the optimal solution for niche requirements in industrial settings.

Energy Efficiency of Industrial Heat Lamps

Energy Conversion Rates and Cost Savings

One of the most compelling aspects of industrial heat lamps is their remarkable energy efficiency. Many systems achieve energy conversion rates of up to 96%, translating to significant cost savings. By delivering heat directly to objects rather than the surrounding air, these lamps minimize wasted energy.

By replacing conventional heating methods with industrial heat lamps, facilities can experience fuel cost reductions ranging between 20% and 50%. This represents a substantial financial incentive for businesses seeking to optimize operational costs while introducing cutting-edge technology.

Comparing With Traditional Heating Methods

When comparing industrial heat lamps to traditional heating alternatives, several factors reveal the clear advantages of infrared systems. Conventional methods typically involve air heating, often resulting in excessive energy expenditure and prolonged processing times. The direct heating nature of infrared technology allows for instantaneous response times, leading to faster operational cycles and thus increasing overall productivity.

Furthermore, traditional methods can lead to a fluctuation of temperatures within industrial environments, whereas industrial heat lamps offer consistent and controllable heat, ensuring uniform quality in the processes they are used for.

Environmental Impacts of Using Industrial Heat Lamps

While discussing the benefits, one cannot overlook the positive environmental impacts associated with the use of industrial heat lamps. With lower energy consumption, these systems contribute to reduced carbon emissions, aligning with increasing global demands for sustainability in industrial practices. The efficiency of infrared heating helps industries adhere to stringent environmental regulations while promoting energy conservation practices.

Moreover, the longevity and durability of industrial heat lamps mean less waste in terms of damaged equipment or frequent replacements, reinforcing a commitment to environmentally responsible manufacturing practices.

Selecting the Right Industrial Heat Lamp

Factors to Consider When Choosing Industrial Heat Lamps

Choosing the right industrial heat lamp involves careful consideration of various factors:

- Application Needs: Assess what process the lamp will support and whether fast curing or gentle heating is required.

- Space Constraints: Determine how much space is available for installation as the physical size of the heating units varies significantly.

- Energy Efficiency Ratings: Look for models with high energy conversion rates to maximize cost savings.

- Control Features: Consider if you need features such as adjustable settings or programmable timers for flexibility in operations.

Understanding these factors can help guide businesses toward making informed decisions that meet their operational needs effectively.

Customization Options for Industrial Applications

Customization plays a vital role in ensuring that industrial heat lamps meet unique operational specifications. Companies like Huai’an Infrared Heating Technology offer tailored solutions, including specialized lamp shapes, wattage preferences, and even custom reflector designs that optimize heat distributions.

This flexibility means that businesses can enhance efficiency and ensure the equipment performs as needed in specific applications, ultimately contributing to improved workflow and productivity.

Recommended Brands and Models

Selecting from reputable brands ensures quality and reliability in performance. Huai’an Infrared Heating Technology is renowned for its patent-pending Gold reflector and Ceramic White coating technologies, which enhance heating efficiency and focus heat precisely where it’s needed. When exploring options, it is advisable to choose brands with proven track records in providing durable, efficient, and effective infrared heating solutions tailored to industrial needs.

Future Trends in Industrial Heating Technology

Innovations in Industrial Heat Lamps

As technology continues to evolve, so do the innovations in industrial heat lamps. The future promises advancements like smart heating solutions that integrate IoT technology for better control and monitoring, and energy-efficient designs that further reduce consumption.

Developments in materials science may also lead to improved durability and efficiency, allowing industrial heat lamps to operate more effectively across diverse environments.

Sustainability Trends in Heating Solutions

The trend toward sustainability in industrial heating is gaining momentum. Manufacturers are increasingly focusing on creating greener technologies that minimize environmental impacts. This shift not only meets regulatory requirements but aligns with consumer preferences favoring environmentally friendly practices.

The innovation in sustainable heating solutions is set to reshape industries, ensuring operations balance productivity with ecological responsibility.

The Future of Infrared Heating Technologies

The future of infrared heating technologies looks bright, characterized by ongoing advancements aimed at enhancing efficiency, sustainability, and functionality. With a commitment to research and development, companies are identifying new applications and refining existing technologies to lead the market.

As industries continue to seek out ways to improve their operational efficiencies and environmental footprint, infrared heating is positioned to remain at the forefront, offering robust solutions that meet both current and future demands.